February 8, 2024

3 Days Venue: Abuja, Lagos, Ibadan

N200,000

$500

Physical

This intensive three-day workshop is designed to equip participants with a deep understanding and practical application of lean manufacturing principles specifically tailored to the food production industry. Attendees will learn how to systematically reduce waste, improve quality, and optimize production processes to enhance efficiency and productivity. Through a blend of theoretical knowledge and interactive activities, participants will gain the skills to implement lean strategies in their operations.

Learning Objectives:

By the end of this workshop, participants will be able to:

Prerequisites:

INTRODUCTION TO LEAN MANUFACTURING IN FOOD PRODUCTION

Module 1: Lean Principles and Foundations

Module 2: Recognizing Waste in Food Production

Module 3: Lean Tools and Techniques – Part I

Activities for Day 1:

MASTERY, MEASUREMENT, AND CONTINUOUS IMPROVEMENT

Module 7: Advanced Lean Concepts

Module 8: Sustaining Lean Improvements

Module 9: Measuring Success and Impact

Activities:

Certification and Closing

MASTERY, MEASUREMENT, AND CONTINUOUS IMPROVEMENT

Module 7: Advanced Lean Concepts

Module 8: Sustaining Lean Improvements

Module 9: Measuring Success and Impact

Activities:

Certification and Closing

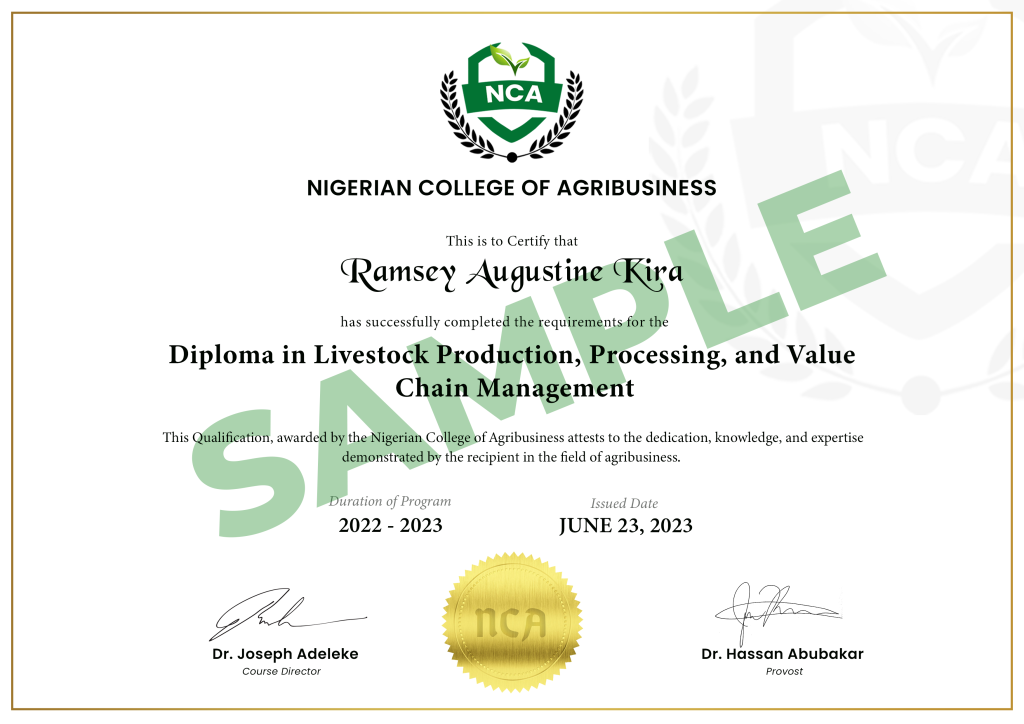

Participants who successfully complete the workshop will receive a certificate of completion, demonstrating their knowledge and hands-on experience with lean manufacturing in the context of food production.

Faculty Members:

The workshop will be conducted by industry experts with extensive experience in implementing lean manufacturing in the food production sector and a solid background in operational excellence.

Beneficiary Bank: Zenith Bank Plc

Account Number: 1228461510

Account Name: Nigeria College of Agribusiness

Do you need any further assistance regarding this program, send an email to: [email protected] or send chat with a program executive on WhatsApp via: 08109532513 (Nigeria), +2349129158989 (International)

Ready to Begin your application process? Click on “Apply Now” to access the application form

Our mission is to cultivate a vibrant, sustainable and profitable agribusiness sector that drives economic growth and social progress across Africa and beyond.

We are committed towards educating a new generation of agribusiness sector leaders that will transform the economic fortunes of the African continent

© NCAEDU 2023 All Rights Reserved.